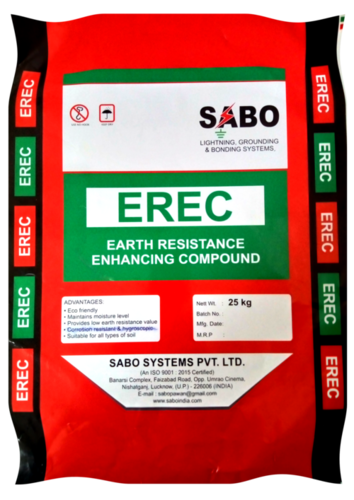

SABO EARTH RESISTANCE ENHANCEMENT COMPOUND

Product Details:

- Product Type POWDER

- Application EARTHING

- Color Blackish

- Dimension (L*W*H) 660.4 * 127 * 914.4 Millimeter (mm)

- Weight 25 Kilograms (kg)

- Warranty 25 years

SABO EARTH RESISTANCE ENHANCEMENT COMPOUND Price And Quantity

- 1750 INR/Bag

- 10 Bag

SABO EARTH RESISTANCE ENHANCEMENT COMPOUND Product Specifications

- 25 years

- 660.4 * 127 * 914.4 Millimeter (mm)

- 25 Kilograms (kg)

- POWDER

- Blackish

- EARTHING

SABO EARTH RESISTANCE ENHANCEMENT COMPOUND Trade Information

- LUCKNOW

- 50000 Bag Per Month

- 1 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- HDPE bag

- All India

- NABL, IEC 62561-7

Product Description

What is Earthing and why is it necessary

Earthing is the grounding or fastening electrical installations to earth In electricity supply systems an earthing system defines the electrical potential of the conductors relative to that of the Earths conductive surface

Installation and maintenance of an effective low resistance earthing system is essential due to the following

Efficiently dissipate heavy fault currents and electrical surges both in magnitude and duration to protect equipment being damaged so as to minimize down time service interruption and replacement cost

Provide a stable reference for electrical and RF circuits at the installation to minimize noise during normal operation

Protection of personnel who work within the area from dangerous electric shock caused due to step potential or touch potential

Characteristics of good Earthing system

Excellent electrical conductivity

Low resistance and electrical impedance

Conductors of sufficient dimensions capable of withstanding high fault currents with no evidence of fusing o mechanical deterioration

Lower earth resistance ensures that energy is dissipated into the ground in the safest possible manner

Lower the earth circuit impedance the more likely that high frequency lightning impulses will flow through the ground electrode path in preference to any other path

High corrosion resistance

The choice of the material for grounding conductors electrodes and connections is vital as most of the grounding system will be buried in the earth mass for many years High hot dipped galvanised electrodes should be used to for this purpose

Mechanically robust and reliable

Should be maintenance free

Earth Enhancement material SABOEREC

SABOEREC is a superior conductive material that improves earthing effectiveness especially in areas of poor conductivity rocky ground areas of moisture variation sandy soils etc NABL Lab tested 0039 Ohmm resistivity It improves conductivity of the earth electrode and ground contact area It has following characteristics

high conductivity improves earth absorbing power and humidity retention capability

noncorrosive in nature having low water solubility but highly hygroscopic

suitable for installation in dry form or in a slurry form

depends on the continuous presence of water to maintain its conductivity

permanent maintenance free and in its set form maintains constant earth resistance with time

thermally stable between 100 C to 600 C ambient temperatures

does not require periodic charging treatment nor replacement and maintenance

suitable for any kind of electrode and all kinds of soils of different resistivity

does not pollute the soil or local water table and meets environmental friendly requirements for landfill

non explosive

does not cause burns irritation to eye skin etc

SABOEREC can be used for all types of earthing Pipe plate electrode etc

Available in 10Kg moisture proof and sealed bags buckets

Required SABOEREC in 2m deep earth pit with 100125mm dia hole 20 kg

Required SABOEREC in 3m deep earth pit with 100125mm dia hole 30 kg

Should be mixed with minimum 6 times volume of water thoroughly and then poured inside earth pit It takes 2 to 4 weeks time in getting fully set

Once set will give lowest possible earth resistance value and maintain it round the year